Automated Machine Tending for Okuma Lathe

Background

Since its inception over 35 years ago, Ergoseal has been a leader in designing and manufacturing advanced sealing solutions. Renowned for their collaboration with engineering teams, they deliver high-performance, custom seals to a diverse global clientele.

The Problem

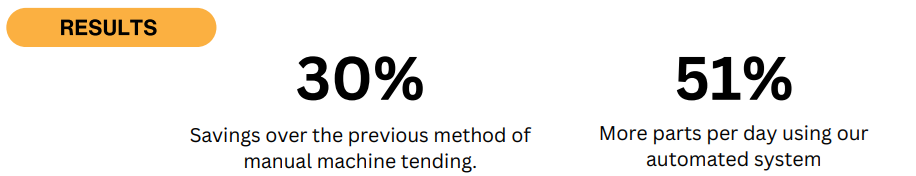

Ergoseal faced a challenge with one of their high-volume, manual operations which required loading heavy parts into an Okuma CNC lathe. Their customer had been increasing their order size, straining Ergoseal’s resources. To address these issues, Ergoseal needed a solution that not only boosted their production rate but also upheld the quality expected by their customers.

The Solution

We innovated a robotic solution utilizing the Universal Robots UR10e, a collaborative robot designed to streamline Ergoseal's production process. The robot was programmed to pick parts from a tray and load them into the Okuma CNC machine. After the machining process, the parts drop onto a specially designed hook where the robot could retrieve them and place them back on the tray. To enhance the system's autonomy and extend unattended runtime, we engineered an automated drawer system. This system allowed for continuous operation by automatically presenting a new trays of parts to the robot ensuring longer uninterrupted production